Dyplast Products has joined the North American region of Kingspan's Insulation Division. Read More

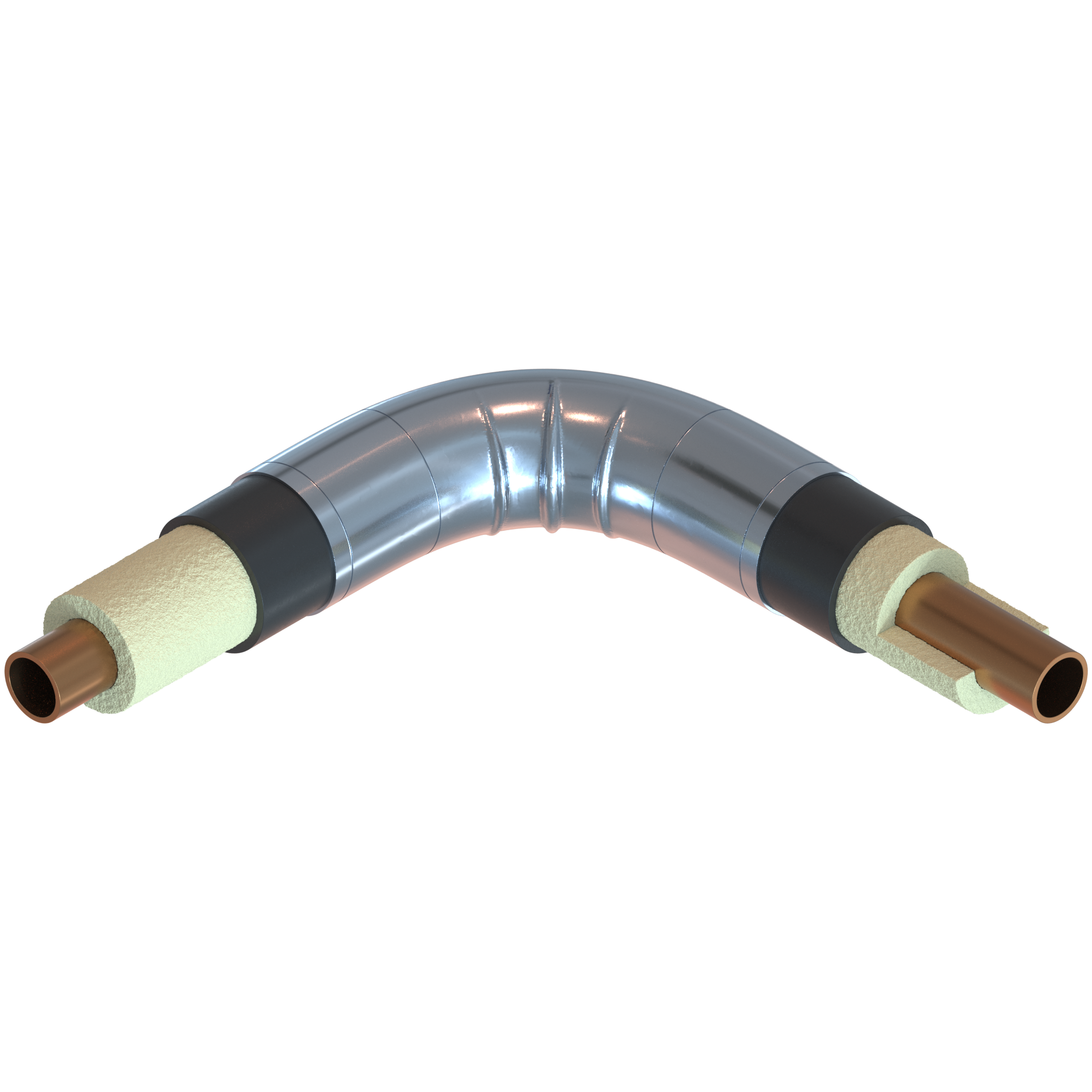

Kingspan Insulation's ISO-C1 2.0 lb/ft3 density polyisocyanurate rigid foam insulation is listed under FM Approval Standard 4880, independently audited by FM. We manufacture ISO-C1 polyisocyanurate as large buns, and subsequently fabricate into insulation panels, pipe insulation, or equipment insulation. Polyisocyanurate insulation is used in a wide range of applications from chilled water pipe insulation to refrigeration insulation to cryogenic insulation. Applications include:

Kingspan polyisocyanurate insulation is available in 2.01, 2.5, 3.0, 4.0 , and 6.0 lb/ft3 densities, and with variable sized buns which can result in reduced waste when cutting to particular dimensions - thus resulting in cost savings.

[ISO-HT pipe insulation is available for higher temperature applications such as hot water pipe insulation and low temperature steam pipe insulation.]

1FM 4880 approval only applies to the 2.0 lb/ft3 density

Typical Physical Properties 1,2,3 | ISO-C1® /2.0 | ASTM C591 Max or Min |

|---|---|---|

Service Temperature °F (°C) | ||

Maximum4 | 300 (149) | 300 (149) |

Minimum | -297 (-183) | -297 (-183) |

12.15 Nominal Density, D1622, lb/ft3 (kg/m3) | 2.02 (33) | ≥2.0 (32) |

12.2 Compressive Resistance (Strength), D1621 psi (kPa) | ||

Parallel | 29.2 (201) | ≥22 (150) |

Perpendicular (Length) | 26.8 (185) | Not specified |

Perpendicular (Width) | 18 (124) | Not specified |

12.3 Apparent Thermal Conductivity, C1776 (aged 6 months @ 73 +/- 4˚F) Btu.in/hr.ft2.˚F | ||

Mean temp of measure -265°F (-165°C) | 0.07 (0.010) | Not specified |

Mean temp of measure -200°F (-129°C) | 0.11 (0.016) | ≤0.13 (0.019) |

Mean temp of measure -150°F (-101°C) | 0.13 (0.019) | ≤0.15 (0.022) |

Mean temp of measure -100°F (-73°C) | 0.16 (0.023) | ≤0.17 (0.025) |

Mean temp of measure -50°F (-45°C) | 0.18 (0.026) | ≤0.19 (0.027) |

Mean temp of measure -0°F (-17°C) | 0.19 (0.028) | ≤0.19 (0.027) |

Mean temp of measure +50°F (+10°C) | 0.18 (0.026) | ≤0.18 (0.026) |

Mean temp of measure +75°F (+24°C) | 0.19 (0.027) | ≤0.19 (0.027) |

Mean temp of measure +150°F (+66°C) | 0.23 (0.033) | ≤0.23 (0.033) |

Mean temp of measure +200°F (+93°C) | 0.26 (0.037) | ≤0.26 (0.037) |

Apparent Thermal Conductivity C518, aged, +75°F (+24°C) | 0.19 (0.027) | ≤0.19 (0.027) |

12.4 Hot-Surface Performance, C411 at 300°F (149°C) Deflection inches (mm) | Pass @ 0.15 (3.8) | ≤0.25 (6) |

12.5 Water Absorption, C272, % by volume | 0.47 | ≤2.0 |

12.6 Water Vapor Permeability (Transmission), E96, Perm-in (ng/Pa.s.m) | 2.49(3.6) | ≤4.0 (5.8) |

12.7 Dimensional Stability7, D2126, % linear change | ||

-40°F, 14 days | -0.8 | ≤1 |

158°F, 97% RH, 14 days | 1.1 | ≤4 |

212°F, 14 days | 0.4 | ≤2 |

12.8 Closed Cell Content, D6226, % | 97 | ≥90 |

1 All properties were measured at temperatures at or near 75° unless otherwise indicated, and all test values were obtained from independent certified testing laboratories.

2 These are nominal values obtained from representative product samples, and are subject to normal manufacturing variances.

3 Average value through the foam cross section of tested sample.

4 Above 300°F, discoloration and charring will occur, potentially resulting in an increased k-factor in the discolored area.

5 Table 1 includes the paragraph numbering system utilized within Section 12 of ASTM C591.

6 Thermal Conductivities (k-factors) at Low Temperatures: ASTM C591 is the Standard Specification for Unfaced Preformed Rigid Cellular Polyisocyanurate Thermal, and is arguably the key Standard used by insulation system end-users and engineer/specifiers to guide decision-making. Compliance with ASTM C591 is often a prerequisite within an insulation Request for Proposal.

7 Frequent and severe thermal cycling can produce dimensional changes significantly greater than those listed here. Special design considerations must be made in systems subject to severe cycling.

The following properties are not specified by ASTM C591, yet are often reported | |

|---|---|

Surface Burning Characteristics8, E84 | |

Flame Spread (@ 4 inch thickness) | ≤25 |

Smoke Density (@ 4 inch thickness) | ≤250 |

Leachable Chloride, C871, ppm | 84 |

Shear Strength, C273, Average of 3 directions in psi (kPa) | 22.9 (157.9) |

Shear Modulus, C273, psi (kPa) | 284 (1960) |

Tensile Strength, D1623, psi (kPa) | |

Parallel | 44.9 (309.6) |

Perpendicular | 28.3 (195.1) |

Tensile Modulus, D1623, psi (kPa) | |

Parallel | 1601 (11040) |

Perpendicular (average) | 928 (6400) |

Flexural Strength, C203, psi (kPa) | |

Parallel | 52 (360) |

Perpendicular | 37 (255) |

Flexural Modulus, C203, psi (kPa) | |

Parallel | 972 (6702) |

Perpendicular | 545 (3760) |

Coefficient of Linear Expansion, E228, Average Value in/in.°F (m/m.°C) | 35 x 10-6 (63 x 10-6) |

Color | Tan |

8 This numerical flame spread data is not intended to reflect hazards presented by this or any other material under actual fire conditions.