Dyplast Products has joined the North American region of Kingspan's Insulation Division. Read More

Kingspan manufactures EPS blocks using a molding process at densities of 1.0, 1.25, 1.5, 2.0, and 3.0 lb/ft3. Kingspan’s production capacities allow us to meet market demands for large or small volume projects. In addition, Kingspan has extensive fabrication capacity and considerable staff expertise to fabricate the blocks into sheets or virtually any shape utilizing computer-aided-design (CAD).

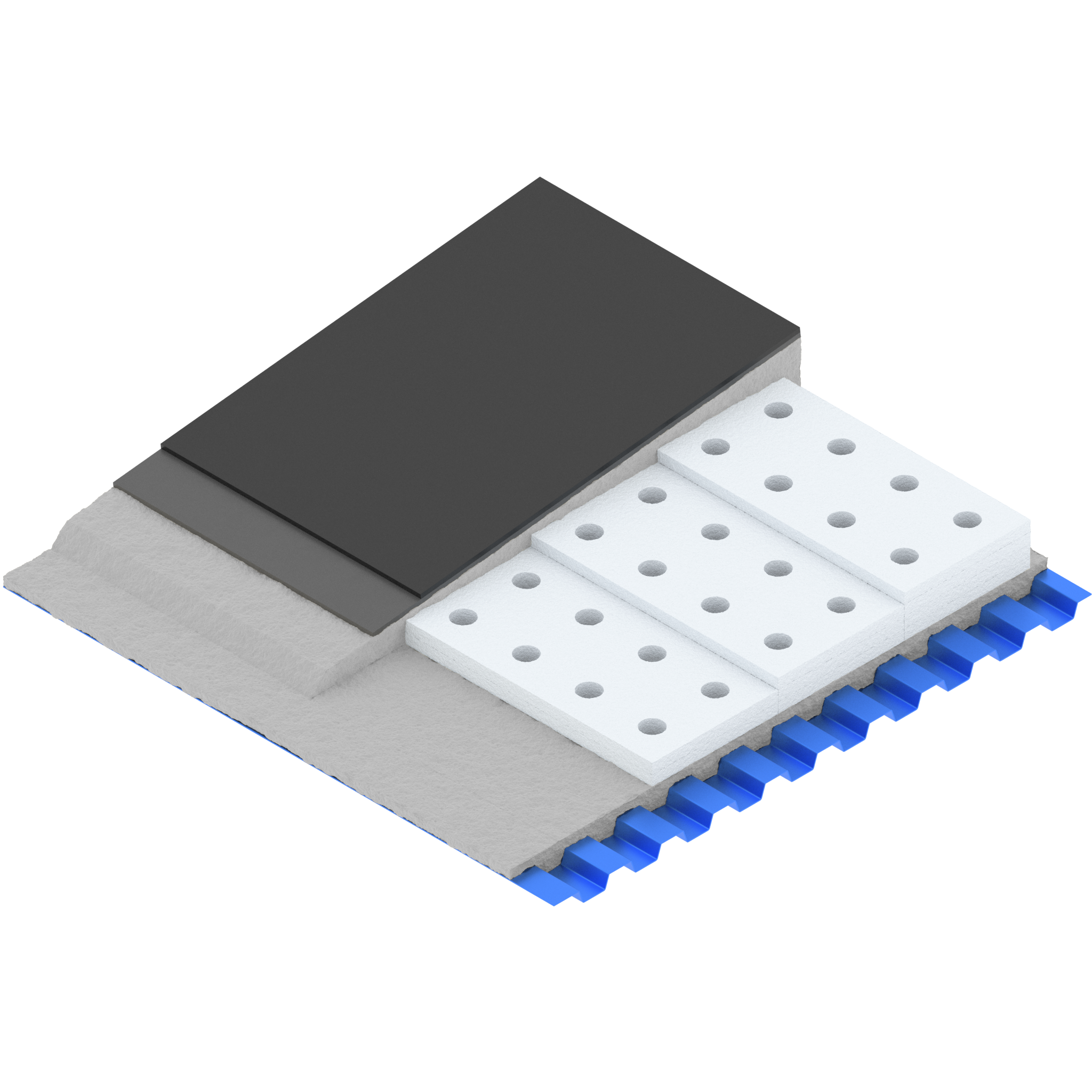

EPS Versatile Applications include:

C578 Data Table | |||||||

|---|---|---|---|---|---|---|---|

Physical Properties1 | ASTM | Units | Type I | Type VIII | Type II | Type IX | Type XIV2 |

Density (min) | D1622 | lb/ft3 | 0.90 | 1.15 | 1.35 | 1.80 | 2.40 |

Compressive Strength at 10% Deformation (min) | D1621 | lb/in2 | 10.0 | 13.0 | 15.0 | 25.0 | 40 |

Flexural Strength (min) | C203 | lb/in2 | 25.0 | 30.0 | 35.0 | 50.0 | 60 |

Thermal Conductivity | C518 | Btu.in/hr. | |||||

75°F | 0.278 | 0.263 | 0.250 | 0.238 | 0.222 | ||

Thermal Resistance (1" thick) | C518 | hr.ft2.˚F/BTU | |||||

75°F | 3.60 | 3.80 | 4.00 | 4.20 | 4.50 | ||

Water Absorption (max) | C272 | % by Volume | 4.0 | 3.0 | 3.0 | 2.0 | 2.0 |

Water Vapor Permeability - | E96 | perm-inch | 5.0 | 3.5 | 3.5 | 2.5 | 2.5 |

Dimensional Stability (max) | D2126 | % | |||||

158°F / 97%RH | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | ||

-40°F / Ambient RH | 2.0 | 2.0 | 2.0 | 2.0 | 2.0 | ||

Oxygen Index (min) | D2863 | Volume % | 24.0 | 24.0 | 24.0 | 24.0 | 24.0 |

1 These are nominal values obtained from representative samples internally or third party tested to meet the requirements of ASTM C578, subject to normal manufacturing variances.

2 Not available from Kingspan Miami facility

ASTM D6817 | ||||||||

|---|---|---|---|---|---|---|---|---|

Physical Properties1 | ASTM | Units | EPS 152 | EPS 19 | EPS 22 | EPS 29 | EPS 392 | EPS 463 |

Density (min) | D1622 | lb/ft3 | 0.90 | 1.15 | 1.35 | 1.80 | 2.40 | 2.85 |

Compressive Strength (min) | C165 | lb/in2 | ||||||

1% deformation | 3.6 | 5.8 | 7.3 | 10.9 | 15.0 | 18.6 | ||

5% deformation | 8.0 | 13.1 | 16.7 | 24.7 | 35.0 | 43.5 | ||

10% deformation | 10.2 | 16.0 | 19.6 | 29.0 | 40.0 | 50.0 | ||

Flexural Strength (min) | C203 | lb/in2 | 25.0 | 30.0 | 35.0 | 50.0 | 60.0 | 75.0 |

Oxygen Index (min) | D2863 | Volume % | 24 | 24 | 24 | 24 | 24 | 24 |

1 These are nominal values obtained from representative samples internally or third party tested to meet the requirements of ASTM D6817, subject to normal manufacturing variances. For additional ranges and specifications, contact Kingspan.

2 Not available from Kingspan Miami facility.

3 Only available from Kingspan Miami Facility.